Titan metal tozy ýokary arassalygy 99% Sferik titanium tozy

Önümiň beýany

Titan tozy dem alyş ukyby bolan kümüş-çal tozy bolup, ýokary temperaturada ýa-da elektrik uçgun şertlerinde ýanýar.Önüm ýokary arassalygy, ownuk bölejikleriň ululygy we ýerüsti işjeňligi ýokarydyr.Adatça howa giňişliginde, pürküji, metallurgiýa we beýleki pudaklarda ulanylýar.

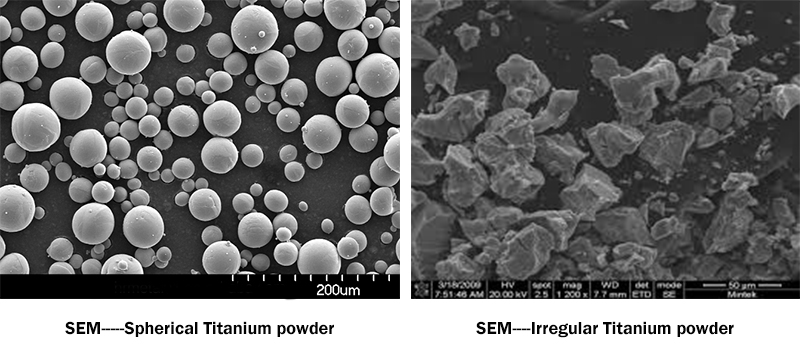

SEM

Spesifikasiýa

| CPTI --- Himiki düzümi | |||||||||

| Ölçegi: | O | N | H | C | Cl | Fe | Si | Mn | Ti |

| -60 | 0.18 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| -80 | 0.2 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| -100 | 0.22 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| -200 | 0.25 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| -325 | 0.32 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.5 |

| -400 | 0.35 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.5 |

| 100-200 | 0.18 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 200-300 | 0.25 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 300-400 | 0.3 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 100-325 | 0.26 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 200-325 | 0.3 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 200-400 | 0.3 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 100-150 | 0.18 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 150-200 | 0.2 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 200-250 | 0.25 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| 250-325 | 0.28 | 0.025 | 0.03 | 0.02 | 0.04 | 0.035 | 0.02 | 0.01 | 99.6 |

| D50 = 3μm | 1.8 | 0.035 | 0.04 | 0.03 | 0.04 | 0.04 | 0.02 | 0.01 | 98 |

| D50 = 5μm | 1.6 | 0.035 | 0.04 | 0.03 | 0.04 | 0.04 | 0.02 | 0.01 | 98 |

| D50 = 8μm | 1.5 | 0.035 | 0.04 | 0.03 | 0.04 | 0.04 | 0.02 | 0.01 | 98.3 |

| D50 = 11μm | 1.5 | 0.035 | 0.04 | 0.03 | 0.04 | 0.04 | 0.02 | 0.01 | 98.3 |

| D50 = 20μm | 1.3 | 0.035 | 0.04 | 0.03 | 0.04 | 0.04 | 0.02 | 0.01 | 98.3 |

Arza

Önüm ýokary arassalygy, ownuk bölejikleriň ululygy we ýerüsti işjeňligi ýokarydyr.

1. poroşok metallurgiýasy

2. poroşok metallurgiýa goşundylary.

3. Aýratyn programmalara titanium süzgüçleri girýär,

4. dürli materiallar,

5. nyşana almak,

6.diamond gurallary

7. polikristally göwher.

Huarui Titan poroşokynyň ýörite tehnologiýa bilen artykmaçlygy

1. kislorodyň mukdaryny peseltmek

2. Ajaýyp suwuklyk bilen ýokary sferik

3. Hemra pudrasy we içi boş poroşok